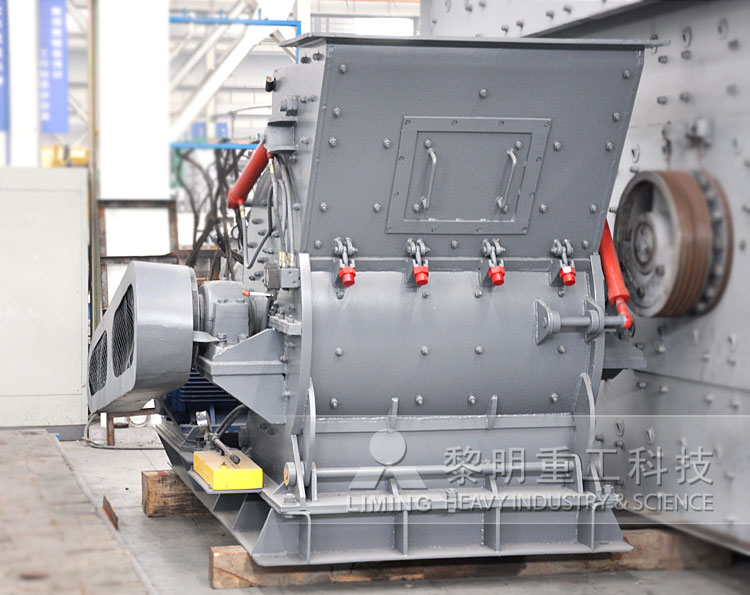

Hammer Crusher’s Overview:

The hammer crusher is one of the main equipment for intermediate and fine crushing the brittle materials with less than intermediate such as limestone coal and other used in metallurgy, building material, chemical and water – power industry, with a feature of big crushing ratio and even product graininess.

Hammer Crusher’s Features:

1. World-level manufacturing technology is adopted, and highest-level raw material is used.

2. Central lubricating device are installed on the machine, so the bearing is easy to be lubricated.

3. Adjustment of the discharge part is more convenient.

The adjustment methods: gasket adjustment, hydraulic assistant adjustment, wedge block and wedge hydraulic adjustment.

4. More advanced movable jaw assembly lengthens life of crusher.

Movable jaw assembly is made from cast piece with high-quality, is driven by two large flying wheels which are made from cast steel. Moreover, heavy eccentric shaft is processed by forged mold. All of these make the JC series jaw crusher extremely reliable.

5. Integral cast steel structure is adopted for bearing seat. Integral cast steel bearing matches well with the crusher frame, at the same time, radial strength of the bearing seat is highly strengthened. However, the separate bearing seat does not have this advantage.

6. Finite element analysis technology is adopted to make the crusher much stronger.

7. Crusher chamber adopts “V” structure which could make actual feed width comply with the nominal one.

8. Bearing with larger model and higher load are used. All JC jaw crusher is equipped with larger bearing compared with same model of normal jaw crusher. Its higher load capacity and effective oil seal will lengthen the life of bearing.

9. A newly designed tooth-shape side plate, makes the available area of jaw plate longer, and enhances the capacity.

10. Pressing bar and support type are used to fix jaw plate.

11. Heavy type protecting plate is intalled for bearing seat, accidental damage of bearing seat is avoided.

12. Supporting bar under jaw plate protects movable jaw and frame from being worn down.

Hammer Crusher’s Highlights:

(1) Inlet large, high crushing chamber to meet the material hardness, fragmentation, the product powder less.

(2) Materials vacant, broken-power small.

(3) New hammer, big impact.

(4) Hammer shaft mounted adjustable hammer and long life.

(5) Raster size adjustable and controllable particle size, particle shape well.

(6) Chassis can be turned over to maintenance more convenient.

(7) Square shank, impact resistance, wear and tear.

(8) Compact, machine rigidity.

(9) Spell structure, handling, ease of installation.

(10) Shock, impact, impact (stone at stone) broken-function, high efficiency, engine wear is small, overall efficiency significantly.

Hammer Crusher’s Working principle:

In the hammer mill machine, the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers. When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them, the crushed products meeting the required size can be discharged by the outlet and become the final products, the large size products are brought back to the crushing area by the hammers for being re-crushed until they reached the required size.

Applications:

1. Hammer crusher can be used in the disposal of coal gangue

Coal gangue is one of industrial solid wastes with the largest discharging. It not only pollutes the environment, but also takes up a large amount of land. However, it is a good material for making foam concrete, and a substitute for cement on a large scale when properly treated. Using coal gangue as raw materials to prepare foam concrete can save energy and minimize the weight of the building. Hammer crusher can be used in this process.

2. Hammer crusher is used in slag cement production

Slag is a byproduct of metal smelting, and hundreds of tons of it are produced every year all over the world in the process of refining metals and making alloys. Like other industrial byproducts, slag actually has many uses, and rarely goes to waste. Slag appears in concrete and aggregate road materials. Hammer crusher can be used to produce slag cement.

3. Hammer crusher is applied in the coal industry

Hammer crusher is often called the coal crusher, coal gangue crusher. This is because that hammer crusher is often used for coke, coal and other brittle materials. By the high-speed rotation body, hammer crusher the material impact each other to crush material, it has a simple structure, large crushing ratio, high production efficiency. The device can be adjusted according to user requirements, change material size, to meet the different needs of different users.

VSI vertical shaft impact crusher

VSI Sand Making Machine introduction: VSI sand making machine (also named VSI vertical shaft impact crusher) is newly developed equipment, based...

READ MOREWheeled-Mounted Mobile Impact Crusher

If you are wise,Wheeled-Mounted Mobile Impact Crusher will be your best choice. Wheeled-Mounted Mobile Impact Crusher'S Overview: Wheeled Impact Crusher...

READ MOREMobile Crushing and Screening

Mobile Crushing and Screening's Overview: Mobile Crushing and Screening is a new designed rock crushing & screening plant, which is flexible,...

READ MORECone Crusher

Hydraulic Cone Crusher has a better performance compared with spring cone crusher and ordinary Hydraulic Cone Crusher: 1. High crushing...

READ MOREC6X Jaw Crusher

C6X series jaw crushers are proudly produced by Liming Heavy Industry, a well-known rock and mineral processing equipment manufacturer in...

READ MOREEuropean Type Impact Crusher

European Type Impact Crusher introductions: European Type Impact Crusher is our latest generation of product with the international advanced-level quality,...

READ MORE LIMING

LIMING