Usually barite barite milling into coarse powder processing (0-3MM), powder processing (20 mesh -400 mesh), and barite deep processing of ultra-fine powder (400 mesh -1250) and powder processing (1250 mesh -3250 mesh) four types.

Barite grinding production line used crusher equipment:

PEW European type jaw crusher

Barite grinding production line used the grinding mills:

MTW European type grinding mill, LM vertical roller mill, LUM Ultrafine vertical mill

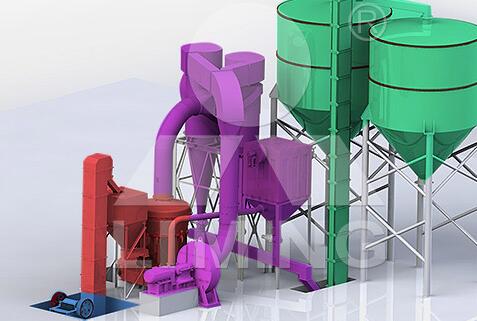

LUM unfine grinding mill is widely applied for the barite grinding processing plants, our company supply the differents capacity LUM unfine grinding mill for our customers in order to meet the different demands.

The first stage: crushing larger barite stone

Barite bulk materials through the crusher to be able to enter the mill feed fineness (15mm-50mm).

Phase II:grinding processing plants

Crushed barite small pieces of material by hoist to the hopper, and then by the vibrating feeder evenly into the mill to quantitative interior polished.

Powder processing generally used LM vertical roller mill, MTW European version of the mill, TGM Super Pressure Trapezium Mill;

Superfine powder processing is generally used LUM Ultrafine vertical mill, HGM medium-speed micro-grinding.

Phase III: Classification

Material through the separator after grinding grading, unqualified powder will be returned to the host after the election, re-grading machine grinding the powder.

Phase IV: powder collector

Powder will meet the fineness with the air through the pipe into the dust collector separated collection, finished powder collected through the discharge port by the conveying means to the storage bin, and then unified with the powder tanker loaded automatic balers or packaging.

New type cement vertical grinding mill sale price in Singapore

Liming heavy industry designed the new type vertical cement mill for sale is one of our most main products(used vertical...

READ MORETGM 160 trapezium coal grinding mill sale price in Pakista

With the Pakistan coal mine industry more and more development, more and more new type coal mill come into the...

READ MORECement making plant used best quality TGM series trapezium grinding mill in indonesia

Cement making plant used best quality TGM series trapezium grinding mill in indonesia Cement plants need the right equipment in...

READ MOREsmallest unit of clinker HGM series roller grinding mill Senegal

Generally speaking, Grinding of clinker is the last and most energy-consuming stage of the cement manufacturing process, drawing on average...

READ MORELM series vertical mill promote energy saving and emission reduction of cement making industry

LM series vertical mill promote energy saving and emission reduction of cement making industry cement lm series vertical mill, cement...

READ MORE26-80tph capaicty pulverized coal mill working principle

26-80tph capaicty pulverized coal mill working principle Coal mining industry has greatly deveopment recently years, the best coal grinding machines...

READ MORE LIMING

LIMING